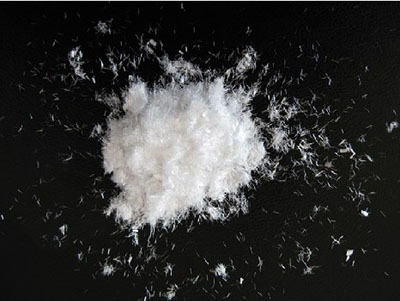

Polypropylene fiber, also known as synthetic fiber, is a kind of synthetic fiber with light texture, strong stability, not easy to rot, not easy to mildew and very durable. Polypropylene fibers are also divided into long fibers and short fibers. Many people think that polypropylene fibers can only be used in textile industry, but also in construction industry. So how can we distinguish the good and bad of polypropylene fibers in the process of application? Liederton, Changzhou, has a magic trick.

There are several methods for identifying polypropylene fibers:

1. Contrast visual measurement: high-quality fibers, neat length, uniform thickness, light and bright color. The quality of doubled silk, slurry silk, coarse silk, coiled silk and greasy stain silk is the best, while the quality of doubled silk and impurity is the opposite.

2. Water bath contrast method: Put 500 ml of water into two water cups, add 0.4 g fibers of the same specifications, stir for 10 seconds, and observe that the high-quality disperse evenly in suspended water; the low-quality can not disperse evenly or in cluster or cluster suspended water or underwater.

3. Odor identification: high-quality fibers: environmentally friendly, tasteless and non-irritating; low-quality fibers: polluted, strong and irritating.

4. Moisture Removal Method: Some inferior polypropylene fibers contain water (it is difficult to feel by hand alone). The moisture content can be measured by drying or drying. Although the price of the fibers is low, it contains water for sale. Assuming that the moisture content is 5%, only 95% of the fibers in a kilogram contain moisture, and the price of the fibers will be 1.05 times the original price.

5. Sunshine irradiation method: Low-quality polypropylene fibers have not been treated with anti-ultraviolet radiation at all because of their cost reduction, while polypropylene fibers lose strength in two years under sunshine, so it is difficult for low-quality polypropylene fibers to play their role in concrete for a long time. As long as the filament is sampled at the site (the consistency between the filament and the polypropylene staple at the site should be strictly distinguished), the tensile strength of the filament can be distinguished after a long time of sunshine and night exposure.

Propylene fibers are very convenient for concrete construction in construction projects. They can be used not only for pouring concrete, but also for shotcreting concrete, precast concrete and cast-in-place concrete. Specific construction technology reference is as follows

1. The amount of polypropylene fibers in concrete is calculated by volume. Generally, the amount of polypropylene fibers in concrete is 0.9-1.2 kg per cubic meter, and the length of fibers is 12-19 MM.

2. Adding fibers does not need to change the mix ratio of the original concrete. For some concrete projects with high crack resistance, it can also adopt adding polypropylene fibers and expansive agent simultaneously. Polypropylene fibers can reduce plastic shrinkage cracks, while expansive agents can reduce dry shrinkage cracks.

3. In order to prevent polypropylene fibers from agglomerating or uneven dispersion in concrete, batch homogeneous addition method can be adopted, and mechanical forced mixing is preferred. Polypropylene fibers can be added to concrete before mixing, during mixing or after mixing. Generally, after adding dry materials (sand, cement, etc.) and water, polypropylene fibers are added. The mixing time can be determined according to the mixing method and the type of mixer. The general mixing time is 30-60S longer than that of ordinary concrete.