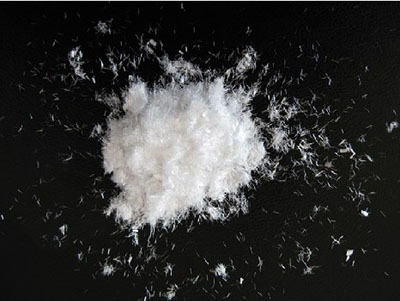

Polypropylene fiber is one of the five most important synthetic fibers in the world. It has many advantages, such as low relative density, good chemical stability, high strength and wear resistance. At the same time, because of its abundant raw materials, simple manufacture and low price, it has developed rapidly and has been widely used in industry and daily life.

Fine denier polypropylene fiber has a unique water and moisture conduction function, and the underwear made of it is smooth and comfortable to wear.

However, polypropylene is a saturated hydrocarbon polymer with strong hydrophobicity and non-polar structure. There are no polar and reactive groups in its molecule that can be combined with any dye molecule. Moreover, polypropylene fibers have high crystallinity, compact structure and lack of necessary pore for dye diffusion. Therefore, dyes, even disperse dyes, are commonly used at present. Polypropylene fibers can hardly be dyed.

As clothing textile materials, the dyeing of polypropylene fibers is an urgent problem to be solved in the further development of polypropylene fibers.

The traditional method of dyeing fibers is dyeing bulk fibers, yarns and fabrics with dyes, but because of its non-polar structure, the common dyes can hardly dye polypropylene fibers. Therefore, in addition to modified polypropylene fibers, polypropylene fabrics sold in the market are generally produced by the original solution coloring method.

Coloring process of polypropylene fibre raw liquor before spinning:

After mixing PP powder with pigment additive powder, extrusion granulation, then extrusion spinning, or directly into the extruder spinning.

Polypropylene particles were added into powder pigments or concentrated masterbatches and extruded for granulation and spinning.

Polypropylene particles and colour masterbatch were mixed spinning on screw extruder of spinning machine.

Colored masterbatch process for producing colored polypropylene fibers has the advantages of good dyeing fastness, washability resistance, low cost and low environmental pollution. It is the main method for producing colored fibers by dyeing raw liquor at present. However, it is suitable for mass production, and has some shortcomings such as not bright colour and difficult to change colour. It is difficult to adapt to the fast changing needs of clothing and other industries.