In order to meet the demand of refractory market, our factory has developed the low melting point explosion-proof fibers carefully and proved by repeated experiments. Through professional testing, the product has excellent dispersibility. It begins to soften at 95 ~C, and has melted completely at 11O ~C, forming a large number of pore channels, which is conducive to the rapid removal of water vapor and effectively avoids the risk of cracking and explosion. This product has replaced the product of PP explosion-proof fiber melting point at 150 160 after being put into the market, it is trusted and recognized by the refractory industry, which will play a strong role in promoting the refractory industry and guaranteeing its quality, and will bring huge economic benefits to the refractory industry.

Scope of application: It is suitable for amorphous refractories such as refractory coatings, burning injection materials, self-flowing materials, spraying materials, plastics, ramming materials, non-fired bricks, etc. It is especially effective in the application of high strength and quick drying amorphous refractories.

Second, product performance: (1) low melting point, no water, additive residues. (2) Tensile resistance, impact resistance, improve the overall strength. (3) Hydrophobic, exhaust, crack-proof and explosion-proof. (4) Shorten the drying cycle, simplify the heating process and prolong the service life of the furnace body.

3. Action mechanism: This product is mixed with other refractories evenly, and baked after moulding. With the baking temperature rising and reaching a certain temperature, the fibers begin to soften, shrink, melt, and finally form pores and carbonize. They distribute in the construction body to form micro-network pores, which can open the water-air passage, reduce internal stress and prevent bursting.

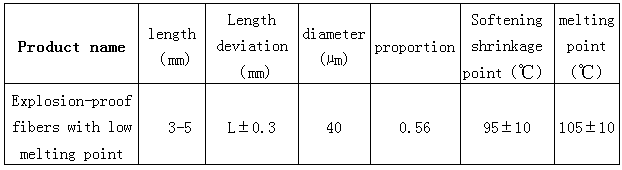

Product specifications and quality indicators: