Scope of application: It is suitable for amorphous refractories of various bulk materials such as refractory coatings, burning injection materials, self-flowing materials, spraying materials, plastics, ramming materials, non-fired bricks, etc. The application effect of explosion-proof fibers on high strength and quick-drying amorphous refractories is particularly remarkable.

Second, product performance: (1) Tensile resistance, impact resistance, improve the overall strength. (2) Hydrophobic, exhaust, crack-proof and explosion-proof. (3) Shorten the drying cycle, simplify the heating process and prolong the service life of the furnace body.

3. Action mechanism: This product is mixed with other refractories evenly, and baked after moulding. With the baking temperature rising and reaching a certain temperature, the fibers begin to soften, shrink, melt, and finally form pores and carbonize. They distribute in the construction body to form micro-network pores, which can open the water-air passage, reduce internal stress and prevent bursting.

4. Usage: (1) According to the type of mixer manufactured by the manufacturer, first put in appropriate amount of cement or superfine powder, then take appropriate explosion-proof fibers to mix with it, and put them into the mixer. (Note: 1-2kg/T is appropriate). (2) Start up the mixing equipment to mix and mix. The explosion-proof fibers were evenly dispersed in the mixture, such as uniformly dispersed, and then the large refractories were put into the mixer for stirring. (3) The specific dosage shall be determined by the manufacturer according to the actual situation and the mixing time shall be controlled at his own discretion.

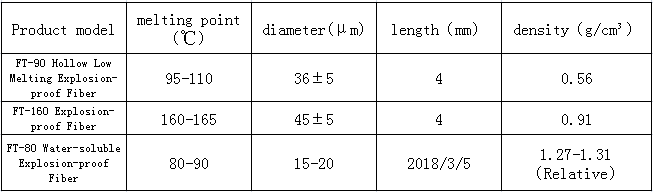

5. Product Specifications and Quality Indicators (RH-3)

Note: Length can be guaranteed according to user's requirements.

High strength, low elongation, white terminal unit, monofilament 7D has strong acid and alkali resistance, low thermal conductivity, low conductivity, safety, non-toxic, moisture content of 0.1%, no water absorption, excellent dispersion.

6. Product Packaging: This product has been packed in PP woven bags, 25 kilograms per bag. Each bag can be packed in small quantities according to the user's needs, so as to avoid static electricity and maintain its purity. The product should be placed in a dry and clean warehouse, damp-proof and sun-proof. After use, the remaining products should be sealed tightly. It can be stored for more than five years.

The explosion-proof fibers are suitable for various bulk materials, such as coatings, castables and other amorphous refractories, shorten the drying cycle, simplify the heating process, and improve the overall service life of the product performance. They have the following three points: 1. Tensile impact resistance, and improve the overall strength. 2. Hydrophobic, exhaust, crack-proof and explosion-proof. 3. Shorten the drying cycle and simplify the heating process. This product is mixed with other refractories evenly, and then baked. With the baking temperature rising and reaching a certain temperature, the fibers begin to soften, shrink, melt, and finally form pores and carbonize. They distribute in the construction body to form micro-network pores, which can open the water-air passage, reduce internal stress and prevent bursting.

Traditional explosion-proof fibers have solid circular cross-section and solid three-leaf profiles. They need to be softened to complete melting before they can form exhaust passage. The melting point is too high, which makes the initial exhaust unobstructed, causes the internal pressure to be too large and destroys the products. Hollow tubular fibers have been studied by our company for many years, and have been widely used in refractories because of their tubular structure. In the initial stage of heating, the tubular collapse forms grooves, which make use of drainage and exhaust to improve the quality and thermal shock resistance of refractories.

The melting point of FT-90 hollow low explosion-proof fibers with low melting point is 110+5 C, which is the indoor index of PE organic fibers.

High-quality explosion-proof fibers must have low melting point and soften during heating, melting point, carbonized formation, organic reinforced skeleton, FT-1.6 um, wall thickness of 6+1.6 um, hollow inner diameter of 22+3 um, ordinary explosion-proof fibers melting point of 165 degrees C can not melt in time at low temperature, resulting in a decline in quality.

There are three kinds of common explosion-proof fibers: PP, PE and PVA.

The melting point of organic fibers and PP organic explosion-proof fibers is 160 C. The effect of application is general. For example, the exhaust gas is not timely, the drying time is long. Although dispersed, water content, oil-containing agent, unit volume is small, the number of fibers is small, and so on.

However, the organic explosion-proof PE fiber (FT-90) has low melting point (110 C), good dispersion, no water and oil, large unit volume, and the number of fibers is three accompaniments of PP. It is only one half of the amount of PP added to improve the economic benefits of using PE explosion-proof fiber.

Although the softening point of PVA organic fibers is low (80 C), there are some problems which are not conducive to the application of refractories. The reason is that the water outlet of refractories can be blocked at the initial stage of water dissolution, the temperature rise is too high or too fast, and it can not work. Therefore, this product is not recommended by our company.