Contact person: Wang Wei

Contact number: 13008286528

Contact person: Manager Wang

Contact number: 13804 196515

Address: Houshan, Xiaodabai Village, Hongwei District, Liaoyang City

Website: en.lyfthx.com

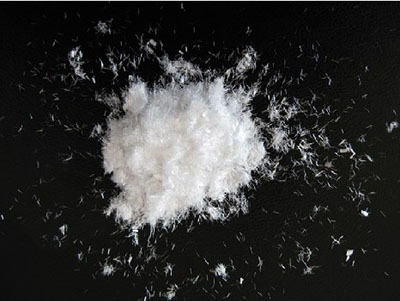

Main advantages of polypropylene fiber!

Good dispersion and good grip strength

High acid and alkali resistance, high radiation resistance

Anti-freezing, Anti-corrosion, Reinforcement and Toughening

Physical Reinforcement, Crack Resistance Reinforcement

Stable performance, safety and non-toxicity

Simple construction, economical and reliable

Improve the fire resistance of hardened concrete. Under the action of high temperature, polypropylene fibers will soften and burn down first, and many channels will be formed in concrete. Water vaporized at high temperature can be discharged along these channels to prevent water vaporization from forming internal high pressure and causing concrete to burst, thus greatly improving the fire-resistant time and fire-resistant grade of concrete.

Improving the impermeability of concrete: After adding fibers, it can effectively prevent the segregation of cement concrete and improve the overall uniformity of the pouring body; significantly reduce the number, length and width of cracks, reduce the possibility of forming through cracks, play the role of blocking the capillary cracks in concrete, and improve the impermeability of concrete. At the same time, the transfer rate of moisture, chloride ion and air in concrete decreases, thus delaying the corrosion of steel bars.

Improve the toughness, fatigue resistance and abrasion resistance of concrete: adding fiber into cement matrix can reduce the brittleness of cement concrete and improve the toughness of the base material. Cement concrete mixed with fibers can withstand tens of thousands or even millions of repeated stresses of static strength, and still keep in good condition. This characteristic is beneficial to some cement concrete structures (such as roads, sidewalks, pavement overlays, warehouse pavement, etc.) which are often subjected to impact fatigue.

The third method is to blend polypropylene particles with color masterbatch on the screw extruder of spinning machine.

Colored masterbatch process for producing colored polypropylene fibers has the advantages of good dyeing fastness, washability resistance, low cost and low environmental pollution. It is the main method for producing colored fibers by dyeing raw liquor at present. However, it is suitable for mass production, and has some shortcomings such as not bright colour and difficult to change colour. It is difficult to adapt to the fast changing needs of clothing and other industries.

Service hotline: 0419-5166770

Company Address: Xiao Dabai, Hongwei

District, Liaoyang City

Village behind mountain

Website:en.lyfthx.com