Contact person: Wang Wei

Contact number: 13008286528

Contact person: Manager Wang

Contact number: 13804 196515

Address: Houshan, Xiaodabai Village, Hongwei District, Liaoyang City

Website: en.lyfthx.com

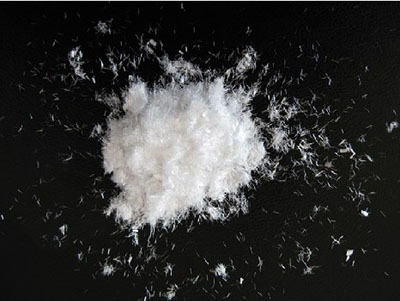

How much polypropylene fibers should be added to the special fibers for cement concrete? Polypropylene fibers can play their role in concrete, which largely depends on the number and uniform distribution of fiber monofilaments in concrete. As the surface of the fibers is covered with a special film, tens of millions of monofilament fibers can be evenly distributed in concrete. Therefore, in general, the amount of fiber in concrete does not need to be too high, 0.6-1.2kg in 1m3 can be added. If the fiber content is 1 m3 concrete and 0.9_is added, the number of monofilament fibers (12 mm in length) in 1 m3 concrete can reach nearly 200 million. Polypropylene fibe

Polyester fibers, polyamide fibers, polyacrylonitrile fibers, polypropylene fibers and so on are commonly used synthetic fibers in life. Many people are not clear about the difference between polypropylene fibers and polyester fibers. Today we are going to talk about the difference between polypropylene fibers and polyester fibers, mainly in two aspects:

1. Polyester fibers are made of polyester as the main raw material, with certain functional masterbatch added. The product density is 136g/cm3. It is soluble in phenol-tetrachloroethane, o-chlorophenol and other solvents. It has very low moisture absorption, acid resistance, high chemical stability and polyamide, and good light resistance. Polypropylene fiber is a kind of high strength polypropylene bundle monofilament fiber, which has the characteristics of simple blending process, low price and excellent performance. Adding concrete or mortar can effectively control the micro-cracks caused by factors such as solid-plastic shrinkage, drying shrinkage and temperature change of concrete (mortar), so as to prevent and suppress the formation and development of cracks.

2. Polyester fibers are generally used for the reinforcement effect of asphalt pavement concrete. The material is 100% modified polyester, while polypropylene fibers are the secondary reinforcement material of concrete. The main difference between polypropylene fibers and polyester fibers is to improve the crack and impermeability resistance, impact resistance, earthquake resistance and frost resistance.

Service hotline: 0419-5166770

Company Address: Xiao Dabai, Hongwei

District, Liaoyang City

Village behind mountain

Website:en.lyfthx.com